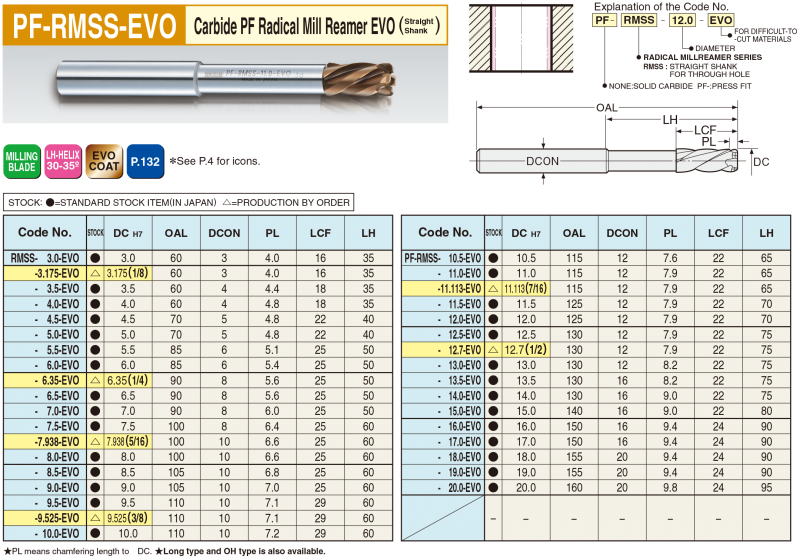

PF-RMSS-EVO

Carbide Radical Mill Reamer EVO is designed for difficult-to-cut materials with an extremely heat-resistant alloy coating

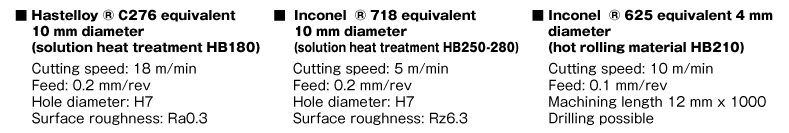

Heat- and corrosion-resistant nickel and titanium alloys such as Inconel R, Hastelloy R, and Waspaloy R are difficult-to-cut materials because of their low thermal conductivity and susceptibility to welding and work hardening.

For this reason, the cutting tool requires a coating that protects your base material from heat and is difficult to weld, while maintaining good sharpness.

The Radical Mill Reamer EVO was designed specifically for difficult-to-cut materials, based on their physical properties.

Note: Since cutting chips are connected, it is necessary to remove the chips, with force by using an edged tool with coolant through or a step tool.

● Cutting angle settings are optimized for difficult-to-cut materials.

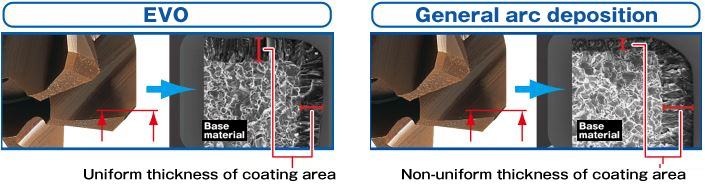

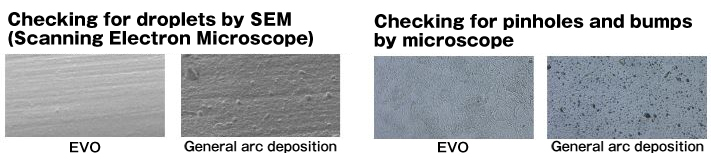

● Uses a high-grade film coating with 1100C° heat resistance, HV3200, and high welding resistance

● Minimizes occurrence of droplets and pinholes to achieve a smooth surface despite arc deposition